Advanced Crosslinking for Next-Generation Semiconductor Packaging

Enabling Cure Without Compromise

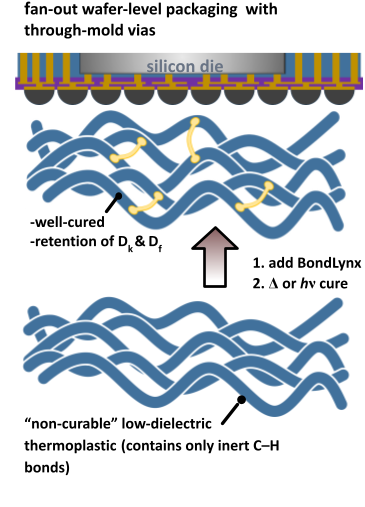

Semiconductor packaging is evolving rapidly—toward thinner, faster, and more complex architectures. However, the polymers best suited for high-performance electronics, such as ultra-low Dₖ and Dբ materials, have traditionally been impossible to crosslink due to their inert chemical structures.

XLYNX Materials changes that.

Our proprietary, PFAS-free diazirine crosslinkers create covalent bonds in materials once considered uncurable, including cyclic olefin polymers (COPs) and other aliphatic thermoplastics. The result is a stable, crosslinked system that retains its ultra-low dielectric properties while gaining thermal and mechanical robustness.

High-Speed Signal Integrity Meets Mechanical Strength

XLYNX crosslinkers are engineered to meet the most stringent demands of advanced semiconductor packaging:

-

Low dielectric constant (Dₖ ) and low dissipation factor (Dբ)

-

Thermal and mechanical stability

-

Moisture resistance

-

Dimensional control

By enabling direct C–H bond insertion using heat or UV light, our crosslinkers allow for tailored curing within existing workflows—without compromising performance.

Designed for the Future of Semiconductor Packaging

XLYNX technology supports next-generation innovations in:

-

Fan-out wafer-level packaging

-

2.5D and 3D hybrid stacking

-

Low-loss interconnects for high-frequency applications

-

Emerging dielectric resins for RF, mmWave, and advanced lithography

With both thermally and photoinitiated crosslinking options, our reagents are adaptable across diverse manufacturing environments and performance targets.

What Makes XLYNX Different

-

PFAS-free formulations that meet global regulatory standards

-

Backed by peer-reviewed publications and a growing patent portfolio

-

First-of-its-kind crosslinking chemistry for inert aliphatic polymers

-

Tailored solutions for specific formulations and performance goals in semiconductor and microelectronics markets

Science-Driven Performance

XLYNX crosslinkers have been shown to reduce free volume and polarizability in polymer systems, preserving low-k properties during photopatterning. By avoiding polar functional groups, they enable reliable patterning of ultra-low dielectric materials while enhancing mechanical strength and thermal durability.

Contact Us

To learn more or request a custom solution for your packaging application, connect with the XLYNX team. Let us help you unlock new possibilities in high-performance microelectronics.