Today, we’re excited to announce the launch of PlastiLynx PXN, an advanced PFAS-free universal primer that modifies the surfaces of hard-to-bond polyolefins to enable strong adhesion with glues, coatings, and dyes.

Today, we’re excited to announce the launch of PlastiLynx PXN, an advanced PFAS-free universal primer that modifies the surfaces of hard-to-bond polyolefins to enable strong adhesion with glues, coatings, and dyes.

Low surface energy polymers like polypropylene (PP) and polyethylene (PE) are highly valued because of their lightweight strength, affordability, and resilience. However, their incompatibility with adhesives has been an obstacle for many applications. Conventional primers and surface treatments offer imperfect solutions to this problem, but a specialty chemtech company in Victoria, Canada, is now offering a different approach with its unique chemical crosslinking technology.

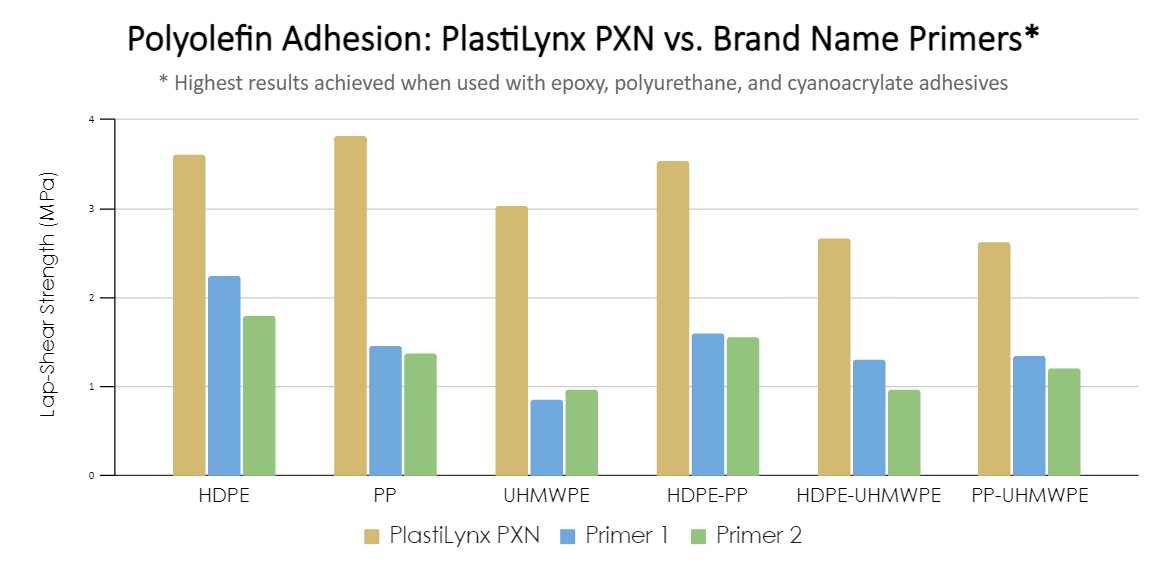

PlastiLynx PXN is the latest and most advanced version of XLYNX’s polymeric diazirine primer, providing improved adhesion while also eliminating fluorine from its chemical composition. Head-to-head against the established brand name polyolefin primers, PlastiLynx PXN provided between 150% to 350% stronger adhesion in PP/PE substrate tests. Simply put, PlastiLynx PXN outperforms every polyolefin primer on the market, and does so by a wide margin. See the results for yourself.

“These latest results really highlight how PlastiLynx PXN is in a class of its own compared to conventional polyolefin primers,” remarked Dr. Stefania Musolino, who led the XLYNX R&D team responsible for the new crosslinker. “Not only did we observe enhanced adhesion across the board, but we also saw strong compatibility with every type of bulk adhesive we tested.”

Unlike commercial polyolefin primers, which are designed to function primarily with cyanoacrylate-type adhesives, PlastiLynx PXN is a universal primer that makes surfaces receptive to all manner of adhesives, including epoxies and polyurethanes. XLYNX Materials tested PlastiLynx PXN with 13 different leading adhesives – many specifically designed for polymers – and in every case, polymer adhesion was significantly improved. By being able to select the right adhesive for the job, manufacturers can choose from a variety of cost-effective adhesives that work with a much broader range of substrates and applications than ever before.

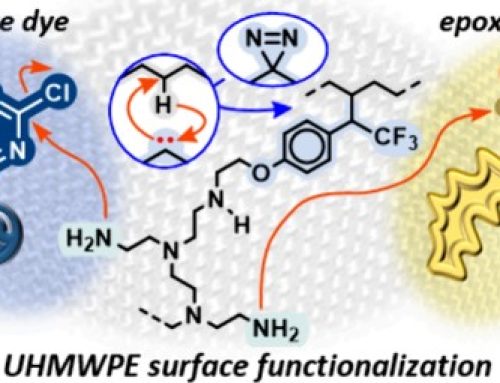

The product’s versatility is a result of the permanent covalent bonds it forms with the substrate surface, leaving a reactive amine layer that is receptive to adhesives, dyes, and coatings. Compared to traditional surface modification techniques for polyolefins like plasma and corona, PlastiLynx PXN is a long-lasting treatment that remains active for months and does not damage the substrate surface.

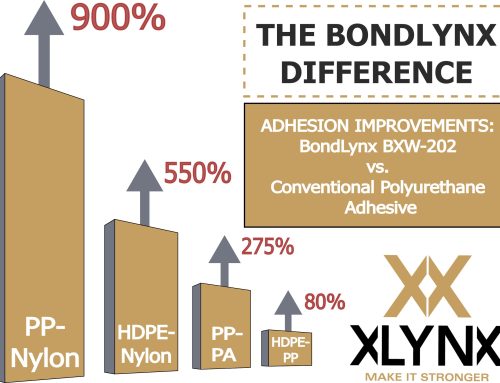

Topically applied and cured rapidly with UV light or moderate heat, PlastiLynx PXN unlocks new design opportunities, manufacturing efficiencies, and dissimilar bonding applications. With the release of PlastiLynx PXN, XLYNX Materials is now able to offer a full suite of advanced PFAS-free diazirine adhesives and primers designed specifically for polyolefin applications.

To learn more, contact us at info@xlynxmaterials.com. Trial quantities of PlastiLynx PXN can often be shipped within a week.