In the marine industry, achieving a reliable bond on polyolefin substrates like high-density polyethylene (HDPE) and polypropylene (PP) has long been a major challenge.

A leading adhesives manufacturer, known for its robust marine products, reached out with a critical need. Their adhesives, although effective in many applications, were underperforming on HDPE and PP. They supplied us with three formulations—two polyurethane-based adhesives (Adhesive #1 and Adhesive #2) —to evaluate whether our advanced primer BXW-202 could bridge this performance gap.

Our Approach

We began by thoroughly cleaning the HDPE and PP substrates with ethyl acetate, ensuring optimal surface preparation. Next, we applied a precise dose of BXW-202—1 mg per sample (3.0 gsm)—and cured the primer with 365nm UV light. In parallel, control samples were prepared using the same protocol, minus the BXW-202. The adhesives were then applied following the manufacturer’s guidelines, and all samples were subjected to lap shear testing in accordance with ASTM D3163.

Dramatic Performance Enhancements

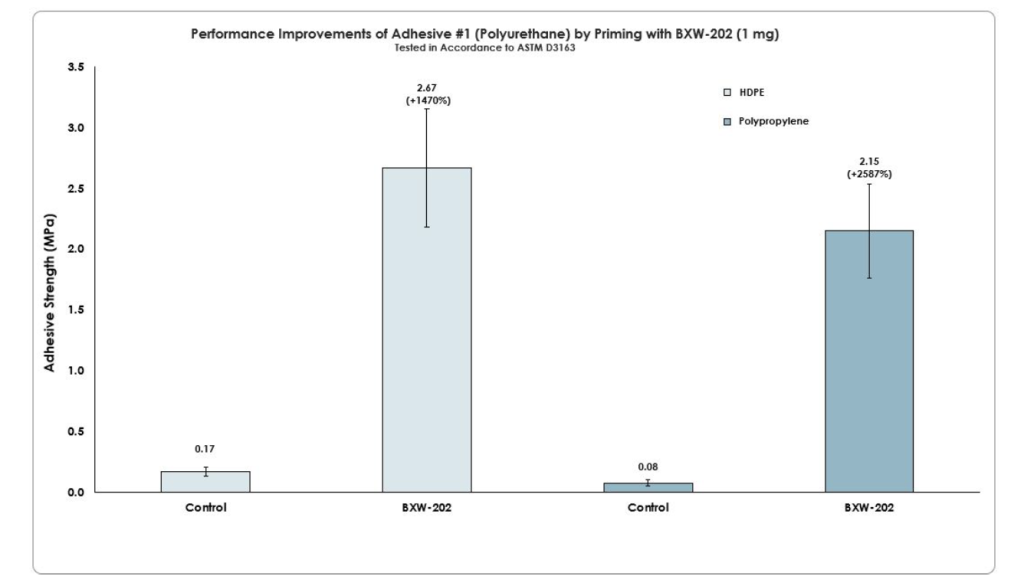

The results speak for themselves. With BXW-202 as a primer, Adhesive #1’s performance soared: from an average lap shear strength of 0.17 MPa on HDPE and 0.08 MPa on PP in the control samples, the treated samples achieved 2.67 MPa on HDPE and 2.15 MPa on PP—representing increases of 1470% and 2587%, respectively.

Adhesive #2 also delivered impressive results; on HDPE, its lap shear strength improved from 0.18 MPa to 1.73 MPa (an 861% increase), while on PP, it jumped from 0.12 MPa to 1.89 MPa (a 1475% increase).

Unlock New Possibilities for Your Products

These remarkable improvements demonstrate the transformative potential of BXW-202. By dramatically boosting adhesion on HDPE and PP, BXW-202 enables marine adhesives to perform reliably in environments where traditional solutions fall short. This means greater durability, enhanced product performance, and a significant competitive advantage in the marine market.

At XLYNX Materials, our commitment to innovation drives us to deliver breakthrough solutions that empower our partners to excel. If your marine adhesives are struggling with polyolefin substrates, it’s time to consider how BXW-202 can unlock new performance levels for your products. Sample sized quantities of BondLynx are ready to ship and our team is standing by to assist you.

Contact us at info@xlynxmaterials.com.