The high-performance electronic devices of the future will place increasing demands on the materials used to produce them, and at the heart of nearly all electronic devices is the printed circuit board.

To preserve high-speed, low-loss signal transmissions and eliminate crosstalk in printed circuit board designs, low dielectric constant and dissipation factors are essential for the materials being used. In addition, these materials must have excellent thermal and mechanical stability, and be able to withstand harsh environmental conditions. Finally, printed circuit board materials must be able to adhere to reinforcement substrates like copper clad laminates and be receptive to modern photopatterning and photolithography applications.

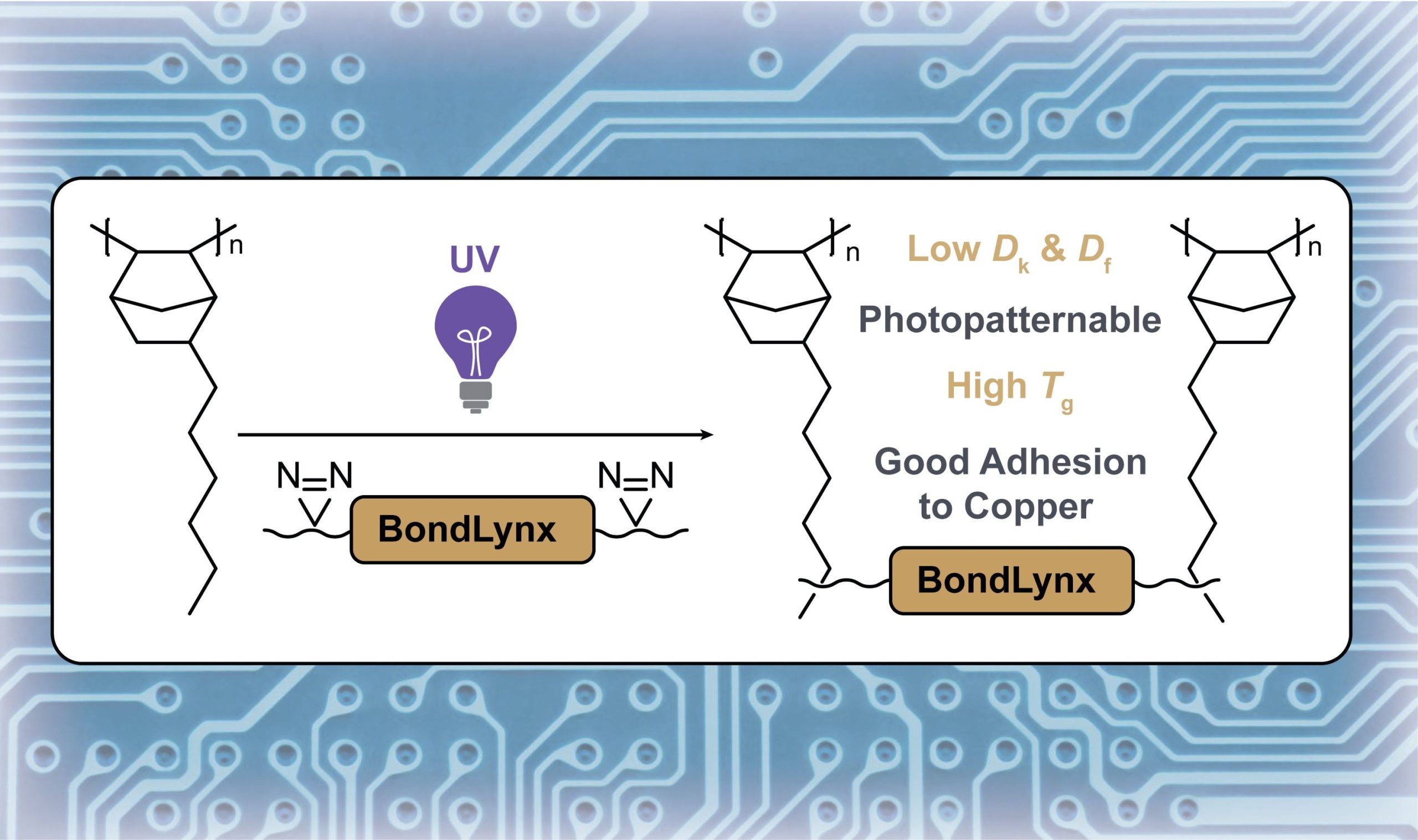

Polymers like polynorbornene are recognized as having the low dielectric properties and thermomechanical stability required for printed circuit boards, but lack the functional groups necessary for adhesion and photopatterning. To add functionality to these materials without negatively impacting their dielectric properties, researchers have been collaborating with XLYNX Materials to develop crosslinked polynorbornenes that are optimized for printed circuit board applications. The encouraging results of this study are now published in Macromolecular Rapid Communications, a scientific journal of the Wiley-VCH (click here to view).

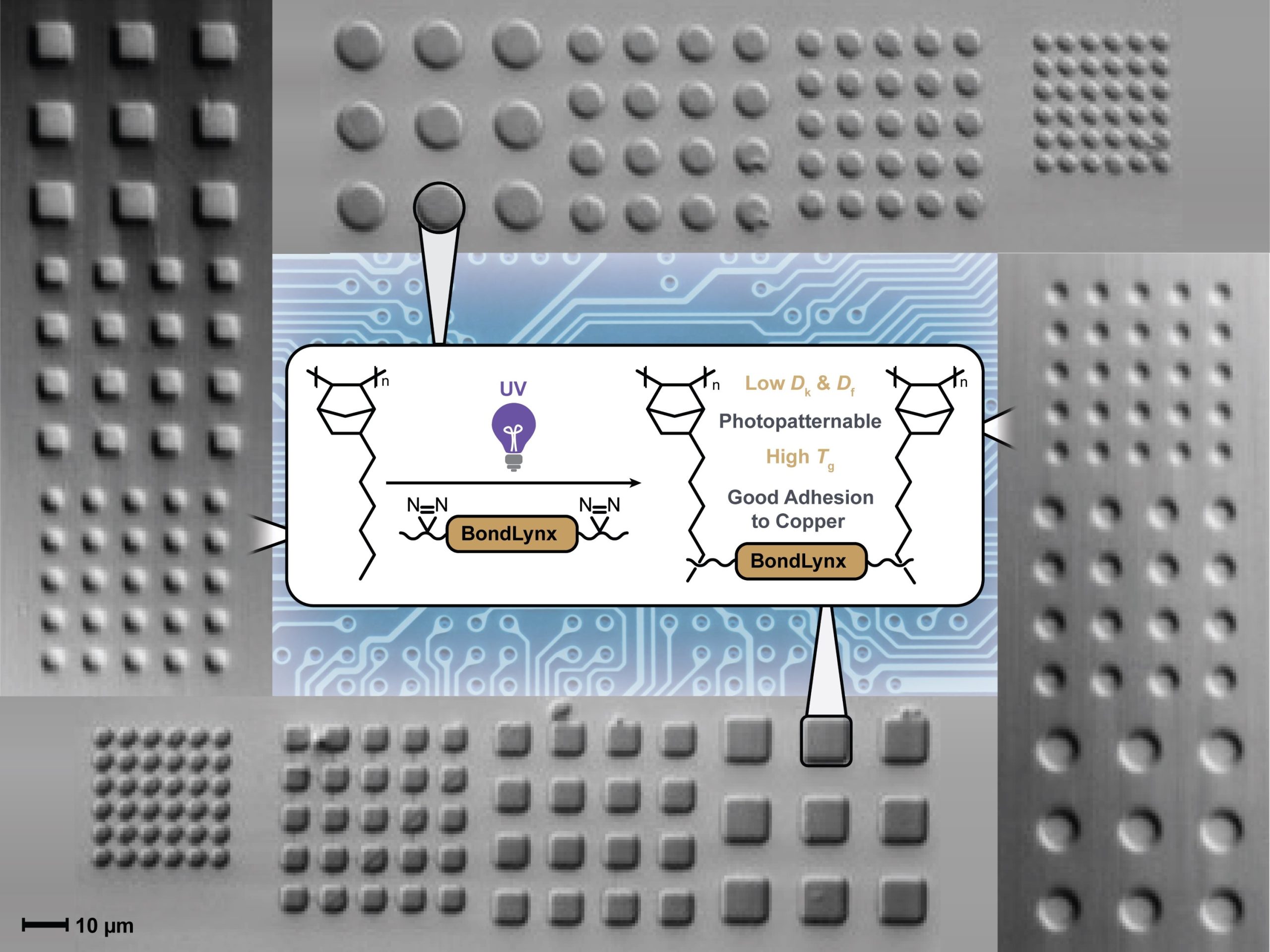

Top-down SEM images of photopatterning results on BondLynx-crosslinked poly(HNB) to leave pillars and holes (see 10 micrometer scale for reference)

In this study, BondLynx was combined with a non-functionalized polymer known as vinyl-addition polynorbornene, or poly(HNB). The resulting crosslinked poly(HNB) demonstrated positive results in negative tone photopatterning and copper clad laminate adhesion tests, while also demonstrating high dielectric performance reliability under heat and humidity testing. Most importantly, this technique preserved the dielectric constant and dissipation properties of the material within acceptable thresholds.

The results of this research demonstrate how functionality can be added to virtually any thermoset or thermoplastic polymer through the use of diazirine crosslinkers without negatively affecting dielectric properties. While this research was focused on printed circuit board applications, these findings have broader implications for advanced microelectronic and semiconductor design in general. As noted by the study’s authors, this also creates new opportunities for advanced printed circuit board applications, such as fan-out wafer-level packaging.

“It’s exciting to see how our diazirine crosslinking technology is enabling new opportunities in printed circuit board design,” remarked Dr. Stefania Musolino, R&D Manager at XLYNX Materials and contributing author to the study. “We look forward to working with manufacturers in this exciting field, as we believe our technology is uniquely suited to this demanding application.”

To learn more about the electronically-optimized diazirine crosslinking technology developed by XLYNX Materials, contact us at info@xlynxmaterials.com. Sample-sized quantities of BondLynx are available to ship, and our team is standing by to assist with your questions and trials.