ADHESIVES & SEALANTS INDUSTRY (ASI), Sept 8, 2022

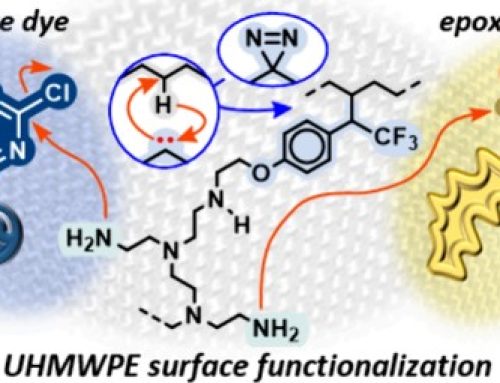

XlynX Materials Inc., a specialty chemical company based in Victoria, Canada, announced the release of PlastiLynx©, a surface-activating primer designed specifically for use with low-surface-energy polymers (polyethylene, polypropylene, etc.). This versatile primer and sizing agent is based on XlynX’s unique diazirine-based crosslinking technology that enables the formation of strong covalent bonds with unreactive polymer substrates (films, solids, fibers).

“Polymers like polyethylene, polypropylene, and fluoropolymers are widely used, but are limited by their lack of reactive cross-linkable groups,” Jeremy Wulff, Ph.D., professor of Organic Chemistry at the University of Victoria and XlynX’s lead chemist, explained. “PlastiLynx solves this by covalently crosslinking with the unreactive polymer to leave a layer of reactive amine groups on its surface, which can then be reacted with other compounds. The potential applications for activated polymers such as this are nearly limitless.”

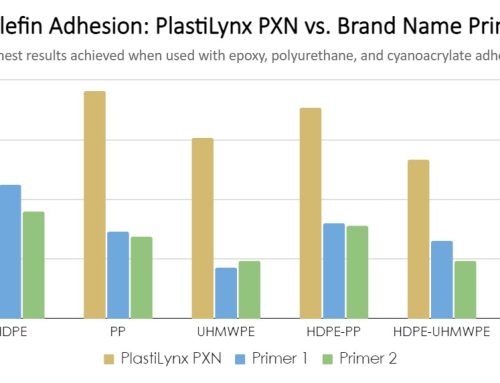

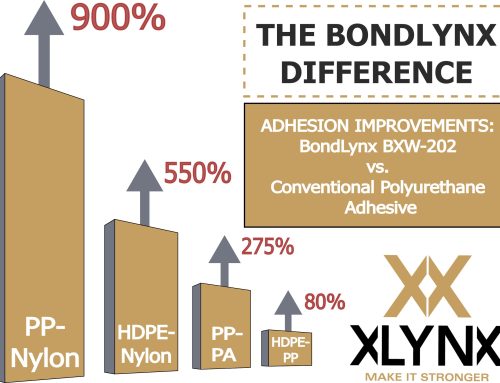

Once treated with PlastiLynx, low-surface-energy polymers can be successfully bonded using a variety of commercial adhesives (epoxy, cyanoacrylate, polyurethane, etc.). To demonstrate the strength of bonds formed in this way, PlastiLynx-primed HDPE substrates were bonded with a polyurethane adhesive and subjected to lap shear testing. The adhesive strength of this primer/adhesive combination was found to be nine times greater than the polyurethane adhesive used on its own.

The XlynX team is currently exploring other applications made possible by PlastiLynx surface-activation. Polymers treated with PlastiLynx are made receptive to amine-reactive dyes (and other coatings) to add long lasting color to notoriously unreactive surfaces and textiles, while PlastiLynx-primed textiles (such as UHMWPE) exhibit higher tensile strength compared to their unprimed counterparts. Further testing is underway around its use in creating lightweight polymer composites and strong lightweight ballistics fabrics.

“This is an exciting time for us as a company,” XlynX’s president, Peter Berrang, said. “While we’re still uncovering the full potential of PlastiLynx, it feels like this could be a real game changer.”

PlastiLynx is non-toxic, water soluble, and easy to apply. It is cured by either UV light (365 nm) or moderate heat (110 °C), and once cured, the activated surface is very stable.

For more information, visit: www.xlynxmaterials.com.