Victoria, BC – XlynX Materials is proud to announce the recent publication of new and encouraging research into one of the most persistent problems of our time; plastic reprocessing and waste mitigation.

Developed in partnership with the Wulff Group of organic chemists at the University of Victoria (UVIC) and published in the German scientific journal Angewandte Chemie, the study demonstrates how diazirine crosslinking technology pioneered by XlynX Materials can be adapted in new and innovative ways to address material challenges. This research project was aimed at two main challenges associated with post-consumer plastic waste; the incompatibility of mixed waste thermoplastics and the irreversible nature of thermoset plastics.

It is estimated that only 9% of all plastics ever produced have been recycled. In part, this is because most post-consumer plastic waste is a mix of thermoplastics like polypropylene (PP) and polyethylene (PE). Attempting to blend these two incompatible substrates together will lead to separation and an inferior reprocessed product. As a result, most thermoplastic waste is destined for incineration or landfills at the end of its useful life cycle.

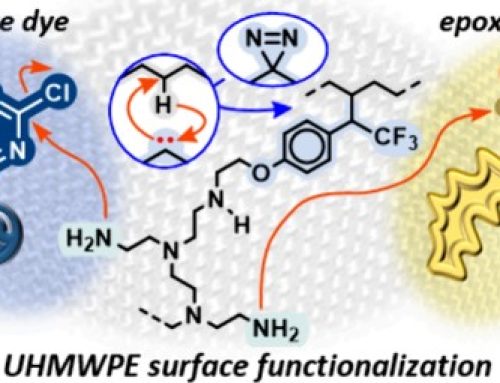

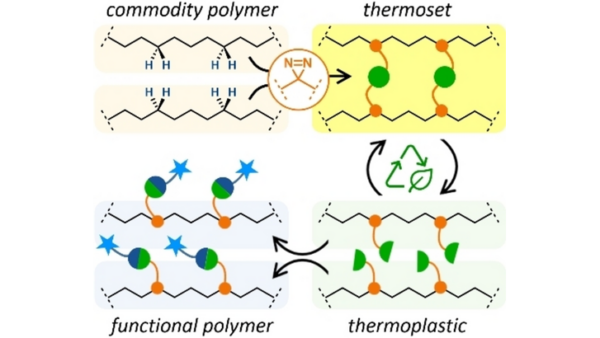

Diazirine crosslinkers, like those employed in BondLynx, don’t distinguish between polymer substrates and can be used to bond dissimilar materials like PP and PE together into rigid thermoset plastics. Thermoset plastics are highly valued by manufacturers for their mechanical strength and thermal resistant properties, and account for about 18% (over 65 million tons) of polymeric materials manufactured each year. However, thermosets pose their own challenges. Once hardened into their final form, they cannot be easily broken down for reprocessing or reshaping. As a result, most thermosets also end up being incinerated or landfilled.

The innovative solution employed by lead investigator Liting Bi (UVIC Phd Candidate) was to introduce a cleavable group to the diazirine crosslinker. In doing so, these cleavable bonds can later be selectively uncoupled through an appropriate input. The success of this study suggests a more sustainable life cycle for plastics could be achieved by upcycling post-consumer waste plastic into high value thermosets which can eventually be broken down for future reprocessing.

XlynX would like to thank Liting Bi for her dedication and efforts on this important work, and congratulate her on her first published study. To read this study, entitled “A Cleavable Crosslinking Strategy for Commodity Polymer Functionalization and Generation of Reprocessable Thermosets”, follow this link: https://doi.org/10.1002/anie.202304708

If you’d like to learn more about XlynX’s diazirine crosslinking technology, we would love to hear from you. Contact us at info@xlynxmaterials.com or visit us online at www.xlynxmaterials.com.