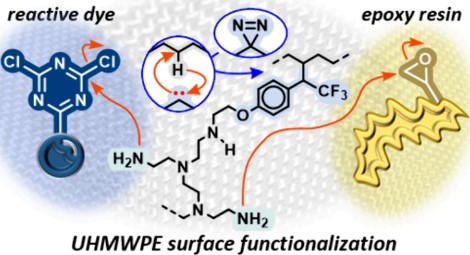

UHMWPE surface modification and textile dyeing made possible with PlastiLynx

Ultra High Molecular Weight Polyethylene (UHMWPE) is a remarkable material, either as a solid plastic or a woven textile. It has a strength-to-weight ratio that is 8-15X greater than high-strength steel, is extremely tough and wear resistant, and has a low coefficient of friction. These qualities are highly valued for automotive, aerospace, defense, and medical applications, but low surface energy also makes it challenging to incorporate UHMWPE into composite materials or to add dyes and colorants to this substrate. In fact, poor dyeability is one of the main factors contributing to minimal use of polyolefin fabrics like UHMWPE in the textile industry, despite its advantages.

This month, the R&D team at XLYNX Materials published new results in Applied Polymer Materials, a scientific journal of the American Chemical Society (ACS), proving how PlastiLynx can be used to treat UHMWPE fabrics for the purpose of dyeing with an extremely high color fastness. This means that rolls of UHMWPE fabric can be permanently dyed after PlastiLynx treatment, and precision color logos or patterns can added to the weave, all without risk of the colors leaching into the environment.

If you’d like to learn more, contact us for more information. Samples are ready to ship, and our R&D team is available to support any questions you have.